Industry 4.0 has been on everyone’s lips for 7 years. Following the example of the Federal Government in 2011, the term stands for the fourth industrial revolution. But is this really what it is?

Or is industry 4.0 “only” an accelerated optimization of processes and value-added chains that had already begun in the 70’s and 80’s and have now really picked up speed with new technologies such as block chains? Shouldn’t we rather understand industry 4.0 as an evolutionary milestone rather than as a revolution? And don’t the additive manufacturing processes with 3D printers deserve to be called a “revolution” because they fundamentally change who manufactures products and where and when they do so? New, fast, inexpensive, high-performance 3D printers are increasingly entering the market and accelerating a development whose significance has yet to be generally understood.

In the first section, this article deals with the topic “Why Industry 4.0 is not the revolution, but the additive manufacturing (3D printing)” and in the second with the question “How and why the revolution in manufacturing is really taking off right now with new 3D technologies “.

Why additive manufacturing (3D printing) – and not Industry 4.0 – deserves to be called a “revolution”.

Over two hundred years ago, the first industrial revolution was triggered by the invention of the steam engine. The second was brought about by the introduction of assembly line production. The third came with the use of computer-aided machines and industrial robots. The interlinking of production with modern information and communication technology networked via the Internet was supposed to be the hallmark of industry 4.0 as the fourth industrial revolution.

According to Wikipedia, intelligent digitally networked systems including powerful processors, digital sensors and real-time networking of complete processes form the basis for Industry 4.0. It is supposed to make self-organized production possible: “People, machines, plants, logistics and products communicate and cooperate directly with each other in industry 4.0. Networking should make it possible to optimize an entire value-added chain rather than just one stage of production. The network should also cover all phases of the product’s life cycle.” (see Wikipedia)

The consulting firm Deloitte sees companies as compelled to rapidly implement Industry 4.0. Rapid introduction is supposed to be necessary because of the trend towards individualisation and a rapidly changing – that is, volatile – demand, to which companies should respond by making production more flexible and introducing new business models.

3D printing helps the industry 4.0 leap forward

Flexible, dynamic, digital – these are the guiding principles of the new production according to Deloitte, which is break through directly to the end user. Customers can personalize specific articles in previously unknown ways according to their individual shopping wishes. In the Smart Factory, this was accompanied by optimized machine utilization and reduced energy consumption. State-of-the-art sensors would automatically monitor wear and tear and perfect maintenance: Industry 4.0 means maximum efficiency of all systems thanks to predictive upkeep – with the goal of zero downtime.

According to Deloitte, the individualization of shoes by online configurators on the Internet is an example of this.

Even “batch size 1” is now feasible for the industry. Until recently, such an approach would have been uneconomical. However, comprehensive digitization and intelligent machines have made it possible in the meanwhile to produce granular workpieces up to single copies, for example with the help of 3D printers for individual products. (See Deloitte, Industry 4.0: Milestone for production – and more!)

Only the additive production with 3D printers allows batch size 1

The casual mention of 3D printing in the Deloitte argumentation does not do justice to the big picture. Rightly put, it should read:

Only 3D printers enable companies to realize individual mass production (batch size 1).

As long as the companies continue working with other manufacturing processes, such as subtractive (e. g. milling) or shaping (e. g. casting) process, an entire flexibilization “around them” makes no sense and sensors and networking are of little use with regard to the cost-effectiveness of batch size 1. Furthermore, building new equipment costs time and therefore money. If the production plants have to be adapted more frequently to individual requirements, that means that set up costs and times increase significantly. The dilemma with the traditional methods of production remains: The optimization of machine utilization no longer helps, tools and machines need capacity utilization in order to achieve optimum economic efficiency. This was and is the reason why mass production has always been concentrated in central locations. BMW, for example, has been producing motorcycles in Germany for more than 50 years at a single location in Berlin. Business economists should not be surprised at this. In 1928 Eugen Schmalenbach already referred to the nature and effect of fixed costs in his famous Viennese speech.

3D printing changes the laws of mass production

3D printers had not yet been invented at the time of the Vienna speech. And for a long time, Schmalenbach was right. But since then it has become possible to manufacture products generically or additively without the use of tools and other machines, thus eliminating the economic necessity for high capacity utilization and large quantities. When using 3D printers, however, the similarity of a product does not represent a cost criterion.

Photo left: Carlos Delgado, through Wikimedia Commons. Photo right: © Formlabs

Different models can be produced on the same building platform without any fundamental change in the cost per piece. Of course, 3D printers must also be written off, which results in fixed costs. The only difference is that mass produced, similar products do not force them to use their production capacities to the full.

It is not Industry 4.0 per se, but only the introduction of 3D printers that presents the opportunity for batch size 1 and the economical production of individual products. Seen in this light, the three former industrial revolutions only concerned the optimization of subtractive operating machines and tools or upstream and downstream processes.

In this sense, there has not been four, but only one industrial revolution hitherto, a revolution that could be summed up as the first phase of the industrial revolution. Enormous technical progress was made after the invention of the steam engine. However, this is an evolutionary process that has made mass production increasingly cheaper, even for new product innovations.

The theoretical model for the first phase of the Industrial Revolution was provided by Adam Smith, the founder of the classical political economy with his major work The Wealth of Nations . In the first chapter, he illustrates the effect of the division of labour using the example of the production of pins. If the division of labour had not made pin production into an independent industry with specialised machines, a worker who was not specially trained in this trade could ” could scarce, perhaps, with his utmost industry, make one pin in a day, and certainly could not make twenty “. In a small specialised factory, on the other hand, ten workers produce about 48,000 pins per day or 4800 pins per worker. “It is the great multiplication of the production of all the different arts, in consequence of the division of labour, which occasions, in a well-governed society, that universal opulence which extends itself to the lowest ranks of the people.” (Adam Smith: An Inquiry into the Nature and Causes of the Wealth of Nations, Chapter 1. 1776, cf. also Wikipedia).

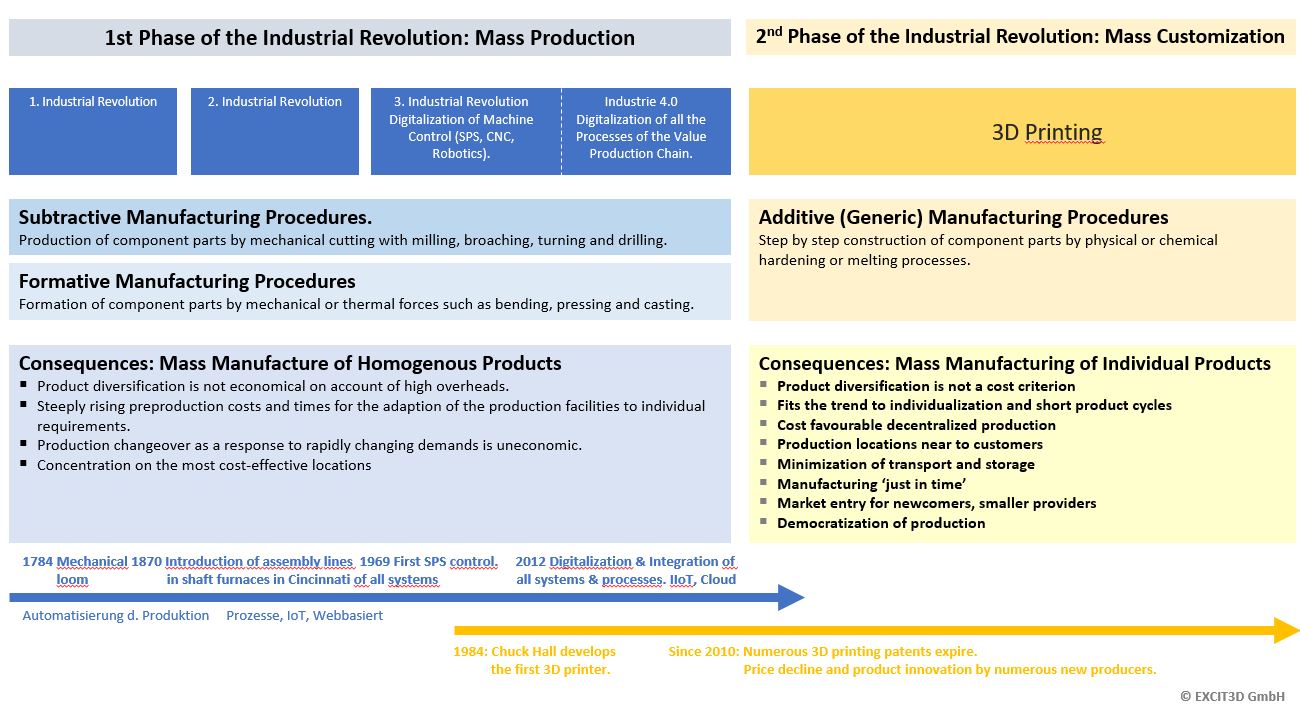

Additive manufacturing and 3D printing should be called the second phase of the industrial revolution, because it allows individual mass production and fundamentally changes the way in which products are manufactured as well as where and when, by whom they are manufactured. (see illustration).

The use of 3D printers renders the benefits of the classic division of labour obsolete. As mentioned above, product homogeneity in additive manufacturing does not represent a cost advantage and the diversity of components does not represent a cost disadvantage. On the same building platform, a wide variety of pins, buttons and much more can be manufactured and constantly varied. In other words, 238 years after Adam Smith published his work, it is time to develop a new theory of production. The following illustration is intended to make a contribution to this.

The changes caused by 3D printing are far more fundamental than those caused by industry 4.0

As described above, 3D printing can help industry 4.0 to introduce mass production or mass customization, as the Americans say. But the effects of 3D printing extend far beyond this. Every industrial company has to rethink the question of vertical integration. For make-or-buy decisions, further alternatives must now be included in the decision-making process. In addition to the question “Do I produce or buy products myself?”, the following options now come into play: “Do I replace the classic production of individual products with additive manufacturing processes?” and “Do I invest in 3D printers or do I use external service providers?” Those who purchase 3D printers themselves can use these products to produce for many other markets. This suggests that there must be a complex mix that takes into account the “break-even point” of the different manufacturing processes for all individual products in terms of their cost.

Taking the example of the “motorcycle” again. Two years ago, the Airbus subsidiary Apworks took everyone by surprise with the Light-Rider, a 35 kilogram electric motorcycle made with a metal 3D printer. As mentioned above, BMW was the only manufacturer of these vehicles in Germany for 50 years. Now an aircraft manufacturer arrives on the scene and produces 500 copies with its 3D printing capacities.

The 3D-printed motorcycle illustrates the scope of the new manufacturing technology in an industrial context. Non-industry vendors can now take advantage of the versatility of their 3D printers to enter new markets. And 3D printing proves its strengths not only through the capacity for individual production. It also gives designers and engineers freedom in design for making products better. The Light-Rider frame made of an aluminium alloy weighs only 5 kg. 3D printing enables resource-saving lightweight construction for the mobility industry. Aircraft manufacturers like Airbus know this – it is not for nothing that they are the pioneers in additive manufacturing. Thinking a little further ahead, the aforementioned “motorcycle” will soon be able to be printed by a dealer around the corner and tailored to the biker’s body measurements. 3D printing enables the production of products when and where they are needed. On the international space station ISS, which is equipped with a 3D printer, an astronaut from NASA recently printed a tool he needed.

The example from NASA shows that storage and long transport routes are a thing of the past. 3D printers enable just-in-time production. And sports shoe manufacturer Adidas brought production back to Germany thanks to 3D printers: in its Speedfactory, it produces individual soles based on 3D scans of its customers’ feet. Which brings us back to lot size 1.

These massive changes mean an enormous change for industry, the markets and fundamental conditions of competition. Already today on 3D model platforms such as Thingiverse or MyMiniFactory, from millions of 3D models the right one can be selected, downloaded in a matter of seconds and produced with your own printer or at a service provider. A service provider can be chosen on 3D printing platforms such as Hubs or treatstock, where tens of thousands of one-man operations and even larger companies across the world offer their 3D printing capacities. The buzzword ‘the democratization of production’ will come true if the dynamic technological development around additive manufacturing continues, if 3D printers become increasingly cheaper, faster and better.

How and why the revolution in manufacturing is taking off with new 3D technologies.

New 3D printing technologies fuel the Industrial Revolution

The new 3D printing technologies must meet three criteria in order to gain acceptance. They must become better, cheaper and faster. There are many signs that these criteria will be met more quickly than might be expected:

Innovative 3D printing processes and materials deliver better results

Additive manufacturing has always had the advantage that it can bring about geometrics which cannot be produced conventionally. But there has also always been criticism here. For example, the strength, the surface of the components or the repeatability of the manufacturing process were often criticized. In the meantime, however, new 3D printing processes, new materials and new software are coming onto the market, which means, on the one hand, a catch-up process with regard to the requirements described and, on the other hand, which makes technical progress possible overall. In the area of materials, for example, 3D printers from the US manufacturer Markforged process composite materials such as carbon or kevlar and achieve aluminium-like strengths. Or there is the German manufacturer Apium, which offers printers that can be used to print the high-performance polymer PEEK 3D. The material is heat-resistant to over 300 degrees Celsius and can be used for making human implants.

Colourful is Beautiful

New 3D printing techniques offer ever more amazing results. For some time, full-colour printers were the domain of Colorjet printers (ZPrinters, nowadays 3D systems) for the polymer gypsum. In the last year, however, the J750 from Stratasys, which uses the Polyjet process to create 360,000 colours offers quality hitherto unknown and, as if that wasn’t enough, has the capacity to combine different kinds of materials.

In the meantime,, the first desktop multicolour 3D printers have become available. The computer giant Apple could soon follow suit.

Always in focus: Metal

The standard for the metal 3D printer were previously powder-bed-based processes (DMLM = Direct Metal Laser Melting) invented in Aachen in the 1990s. There are now completely new approaches. The 3DMP procedure of the Berliner Start-up Gefertec is notable. By means of arc welding technology, even very large workpieces made of different metallic workpieces are produced in a kind of deposition welding process. The approach of the Israeli manufacturer XJet and its patented NanoParticle Jetting (NPJ) technology is spectacular: it allows objects to be made not only out of metal but also out of ceramic.

And that’s not all. So-called Fused Deposition Modelling (FDM) processes, which were previously used to process plastics such as ABS and PLA, can now also be used for metal. Two manufacturers are emerging as potential technology leaders: Desktop Metal and Markforged.

Even if further processes (e. g. sintering) are required after 3D printing, this type of process can usher in a new era of metal 3D printing.

Traditional metal-working companies must be vigilant and should urgently address the issue of additive manufacturing. The industrial revolution triggered by 3D printing processes does not stop at the metal industry.

New speed records

If you work with 3D printers, you probably often want the objects to be finished more quickly. In most cases, attempting to be faster comes at the price of quality. Compared to, for example, injection moulding as a manufacturing process, 3D printing has so far been more of a snail, although it must always be stated that this is not without expending costs and time for producing the mould. Nevertheless, the faster printing processes that are now coming onto the market are a blessing for individual mass production.

The TED-Talk of the Carbon3D company founder Joseph de Simon in 2015, entitled “What if 3D printing was 100x faster?” marked the beginning of the “Speed Rush”. During the 10-minute talk, the 3D printer named M1 produced an object of about 10 cm.

In the meantime, the company Adidas has purchased 50 of these devices to produce 100,000 pairs of individual sneakers this year.

The fact that light-curing processes currently achieve the fastest results is also shown by the US start UNIZ. The top-of-the-range zSLTV-T, which was advertised in a Kick-starter campaign and uses LCD (SLA) technology, has a construction volume of 52.1 x 29.3 x 65.1 cm and caused a sensation with a speed of 7,000 cc/hr (solid) and 56000 cc/hr (envelope speed). That means that 20 dental models can be produced in less than five minutes. (More about this here…)

Not only that, but 3D prints could be finished in seconds instead of minutes or hours. The Lawrence Livermore National Laboratory recently unveiled a new technology designed to produce complete 3D shapes in seconds with holographic light fields. With a total of three laser beams directed at a container filled with resin, the researchers at the institute generated a 3D light pattern of the object to be printed (hologram). Its structures were then created in a single step in just 10 seconds (more…). Mass customization at high speeds is not only possible with faster printers, but also with the simultaneous use and automation of many devices. The SLA desktop pioneer Formlabs wants to achieve exactly this with its Form Cell.

The costs of additive production fall dramatically across the board

In the past, the expiry of patent rights often triggered the emergence of new competitors and a resulting fall in printer prices. By now, the patents on many 3D printing processes have expired – with remarkable consequences:

The first full-colour 3D printer, the Da Vinci Color is available for just 3,600 EUR and for reliable FDM-3D printers with a large installation space in China, you need to pay only a few hundred EUR. In the metals sector, the new FDM-3D printers mentioned above are also ringing in a massive fall in prices.

The same applies to the new metal 3D printing processes, some of which are much cheaper than conventional powder-bed-based processes.

In the field of the so-called SLA (stereo lithography) process, Formlabs has the merit of making SLA printing affordable. Dental laboratories and jewellers are particularly pleased about this.

The above-mentioned manufacturer UNIZ presently follows. Its fast devices are not only supposed to deliver good surface quality, but are also extremely cheap. 20 dental models in 5 minutes can be produced for purchase prices of less than 10,000 EUR. Professional production at lowest prices. The possibilities are endless.

Until now, additive manufacturing has only become established in those industries where its advantages have proven to be most significant, e. g. in medical technology (individual implants, orthoses, hearing aids) and aviation (due to lightweight construction). With falling prices, it will cover large parts of the manufacturing industry in the future.

Within the value-added chain, production resources require ever lower investments thanks to additive manufacturing. But if everyone can produce at a much lower cost, the competitive advantages will be in other areas. The product idea, functionality, design and material will be far more decisive or the creation of value in the future.

Summary

- Industry 4.0 is only an evolutionary development of the so-called 3rd Industrial Revolution.

- Industry 4.0 can only achieve batch size 1 or individualized mass production with 3D printers.

- Since 3D printing is changing how and for who products are manufactured, as well as the when and where of their production, additive manufacturing is the real next industrial revolution.

- With new, powerful, super-fast and inexpensive 3D printing processes, the Industrial Revolution is taking off.